Brock

Well-Known Member

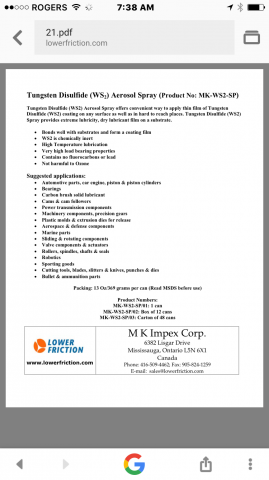

This has been stated as the best coating for fighting friction and heat ?

High heat properties, low friction and microns thick. What's not to like?

Benefits and Capabilities of Tungsten Disulfide (WS2)

http://www.microsurfacecorp.com/amp/ws2_tungsten_disulfide.html

https://www.ws2coating.com/ws2dryfilmlubricant/

High heat properties, low friction and microns thick. What's not to like?

Benefits and Capabilities of Tungsten Disulfide (WS2)

- The WS2 low friciton coating overcomes or reduces mechanical lubrication problems which improve performance and extend service life.

- Reduces friction to lower emissions as less fuel is used for a given power level when applied to engine parts such as pistons rings, cams and bores.

- Eliminates and reduces costly maintenance problems that cause breakdowns and expensive downtime by stopping galling, fretting and friction caused by dissimilar metals and their different hardness factors.

- Maintains the dimensional integrity of the substrate to within 1.0 micron with no build-up. Tungsten Disulfide (WS2) particles will not adhere to themselves so the coating thickness is limited to 1.0 micron.

- Withstands loads to 100,000 psi (or load capacity equal to substrate) and operates in the temperature range of -460°F to 1200°F (-273°C to 650°C).

- Offers 100% Lubricity throughout its texture.

- Is inert, inorganic, non-toxic, non-distortive, non-corrosive and resistant to most fuels solvents. It is compatible with and enhances the performance of all oils and greases.

- Resists carbon build-up due to its extremely low co-efficient of friction, less than half that of graphite, Moly (MoS2) and Teflon.

- Molecularly bonds to all materials and platings and can only be eliminated by removing the bonded substrate.

- No bakeout or heat curing is required for the application of Tungsten Disulfide (WS2).

http://www.microsurfacecorp.com/amp/ws2_tungsten_disulfide.html

https://www.ws2coating.com/ws2dryfilmlubricant/

Last edited: