Jimisawesome

New Member

- Messages

- 8

- Age

- 35

- Location

- Billings

- Country

- USA

- Years Snowmobiling

- 1

- Snowmobile

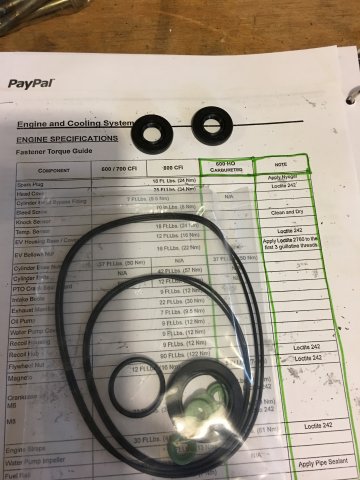

- 2007 Polaris RMK 600 HO 155

Hey everyone! My family has moved to Montana and just picked up a sled! I have never riden a snowmobile before but have riden quads and motorcycles my whole life. (Never lived close enough snow trails or anything like that). I just picked up an RMK 600 HO 155. I've been told it's not really a beginner sled which is fine (can grow into it). More importantly it is not running. Looks like it needs new piston rod and was broken down by a shop. I have started cleaning up all the components and engine bay however I'm need of some guidance.

A). I am trying to find out exactly what sled I have. I found a model number decoder somewhere online but cannot locate now. It broke each section of the number down and had a legend.

B). I am leaning towards buying some of the tools I need to pull bearings from crankshaft. Then install new piston and press the bearing back on. I know I have to time and true the shaft but am somewhat confused(for now) on how exactly I do that. Any advise would be appreciated.

Thanks in advance!! Cheers

Jimbo

A). I am trying to find out exactly what sled I have. I found a model number decoder somewhere online but cannot locate now. It broke each section of the number down and had a legend.

B). I am leaning towards buying some of the tools I need to pull bearings from crankshaft. Then install new piston and press the bearing back on. I know I have to time and true the shaft but am somewhat confused(for now) on how exactly I do that. Any advise would be appreciated.

Thanks in advance!! Cheers

Jimbo