Brock

Well-Known Member

First off, this is my opinion and findings. It's not the law or the exact to what's going on with every sled.

We started doing all this back in February of this year.

The thing is, I have proof of dyno (hundreds)sheets from good one's to one bad one. I also have over a dozen video's of the digital wrench while sled's were on dyno.

My findings are not speculating(chasing my tail with heat shields and cooling), it's all factual data from the dyno to digital wrench.

Since the Polaris Team tips came out about low RPM and probable causes. I believe that 90% of the guys that think they have a problem fall into what Polaris has mentioned in their team tips. Sorry guys, it's the cold hard truth. To prove my point. A guy brought his axys to DTR and said it was under performing and couldn't get it to go. Well, let's just say the dyno showed he made tons of HP and torque, so it was all in his CVT system(clutching).Internet chatter can be evil to some guy's. Off to his dealer to get it clutched after he spent $250.00 for dyno.

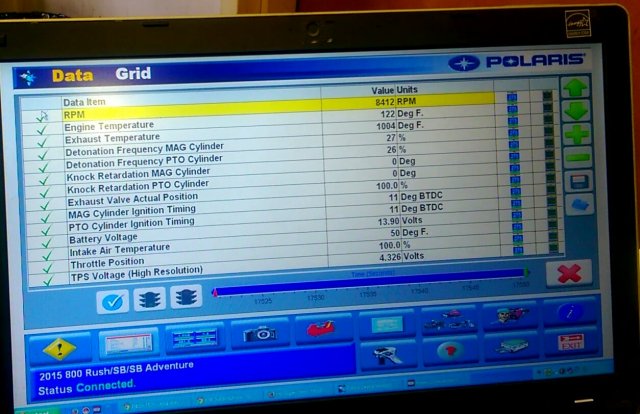

As I mentioned in another thread on here, everything on this under performing sled was checked over. We did two full service reports on digital wrench while sled was idling and was sent to Polaris. We did a system check on digital wrench on every component that can/could be checked. I also checked resistances,continuity,voltages all with a Fluke multi-meter to verify digital wrench findings were the same.Everything was within spec and parameters but the TPS and T-Map was a little off. All good components stayed on sled that were within spec and parameters.To back up our findings this was all compared to a good running axys that made great HP and torque.

The only we didn't do was change the wiring harness.

On to the good stuff.

Several trips to dealers and dyno to figure all this out is hard but it is paying off. I won't stop until it's within 1% of all the great sled's dyno'd.

Summary: this has only rev'd 8200 RPM tops ever and the digital wrench history backs this up. I clutched and geared it to 8100 RPM as it fell hard after this.All my field testing proved what I was doing was correct to dyno sheets.

All dyno runs are done in three's and consistant with every sled done at DTR to keep it the same results.

First:engine temp was around 75f and rev'd around 7000RPm to get pipe heat to 900f

second:engine temp was around 120f now and get pipe to 1000f

third:engine temp was over 135f+ and pipe a good 1050f+

put on something new and repeat............

This sled makes HP to 8100 RPM and then falls hard. The other good axys dyno'd make power to 8300 RPM+.

We changed ECU's with a great dyno'd axys and still the same(thanks Heath )

)

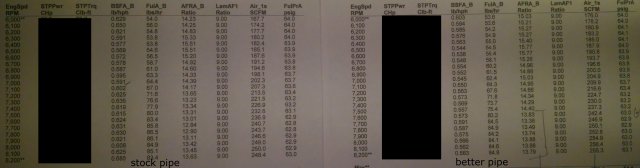

The problem was the bsfa's were to rich(mid 0.65's) from 7200 RPM up. The cfm's were down a little. Afr was ok. We needed to get the bsfa's down and the cfm's(scfm) up.

This sled made around the same HP and torque right up to 7500-7600 RPM as great sled's dyno'd then started falling after this. This is why I'm mentioning the bsfa's and scfm's. This seemed to be hurting this sled up top. From 7600 to 8400 RPM. There are ways to get this down and up.

After tons of dyno runs,we suspected the pipe, pipe sealing and muffler(back pressure). We put another pipe on that fit better and snug around the y-pipe and tried it.This run showed promise as the bsfa's came down(mid 0.55's) and the scfm's came up 7.The stock pipe was not putting heat in the pipe and the is why the bsfa's were in the mid 0.65's and scfm's were down. When in this state the sled would only make power to 8100 RPM and that's it.The bsfa's and scfm's were hurting this sled up top. By changing to a better pipe the bsfa's and scfm's were a lot better just because of this. Putting the pipe on brought the RPM up 150, which now made better HP and torque.Were suspected the pipe and muffler on this one and probably more out there like this particular one.

With the stock pipe on, the pipe would only get to 1050f on third dyno run. By this time the engine temp was to high.Most great HP axys sleds were getting good pipe temp at first and second dyno runs.This is were engine temp was from 90f to 120f and the pipe would reach 1050f. By the third run the engine temp was up 135f +. These were all done the same on all axys sled's so it was consistent and accurate findings.The stock pipe I had on there wouldn't get the pipe heat the great HP axys sled's did. Like I said, it toke the third dyno pull to make good pipe heat and by this time the engine temp was to high and hurt the numbers.

By putting on another pipe that fit better it made better HP/torque, brought the bsfa's down to mid 0.55's and the scfm's up 7. This also was now getting pipe heat to 1050f on the second dyno run now and the engine temp was from 110-130f which is better to have a cold engine and hot pipe. By the way,on DTR dyno the 1050f pipe temp is were these sled's are making great power but also to have a colder engine( around 110-130f).

I'm blaming the pipe,muffler/can TPS,CVT system and Polaris's poor fuel mapping from factory. To back up my findings the pipe was just proven above. The TPS are used in everything Polaris makes from quads to sxs,to sled's for years. The TPS needs to be around 0.705 volts at base, 0.913 at idle,and 4.240-4.330 at WOT. As for the poor Polaris fuel mapping. Changing the fuel and some timing ALONE gets 4-5 HP more and 2lbs of torque. I blame the warranty department for this way to safe fuel mapping. There is a lot left on the table for fuel/timing.

This is were I can see guys getting low RPM/fade in the field,all this combined. The CVT system,ECU fuel mapping,bad pipe/fitting pipe,TPS out of parameters,valves, etc.....etc......

Pulling raw fuel through the pipe makes no HP and would drop PM down in the feild, add a TPS that's richening the fuel and the bad fuel mapping,bad clutching,and this is were you'll see an RPM drop/fade I think. Sometimes the sled is pulling and putting some heat in the pipe, sometimes there's no heat in the pipe to make HP and this drops RPM everytime.

I'm including some pictures and stuff of the findings.

I hope this helps answer some questions as I have more.

We started doing all this back in February of this year.

The thing is, I have proof of dyno (hundreds)sheets from good one's to one bad one. I also have over a dozen video's of the digital wrench while sled's were on dyno.

My findings are not speculating(chasing my tail with heat shields and cooling), it's all factual data from the dyno to digital wrench.

Since the Polaris Team tips came out about low RPM and probable causes. I believe that 90% of the guys that think they have a problem fall into what Polaris has mentioned in their team tips. Sorry guys, it's the cold hard truth. To prove my point. A guy brought his axys to DTR and said it was under performing and couldn't get it to go. Well, let's just say the dyno showed he made tons of HP and torque, so it was all in his CVT system(clutching).Internet chatter can be evil to some guy's. Off to his dealer to get it clutched after he spent $250.00 for dyno.

As I mentioned in another thread on here, everything on this under performing sled was checked over. We did two full service reports on digital wrench while sled was idling and was sent to Polaris. We did a system check on digital wrench on every component that can/could be checked. I also checked resistances,continuity,voltages all with a Fluke multi-meter to verify digital wrench findings were the same.Everything was within spec and parameters but the TPS and T-Map was a little off. All good components stayed on sled that were within spec and parameters.To back up our findings this was all compared to a good running axys that made great HP and torque.

The only we didn't do was change the wiring harness.

On to the good stuff.

Several trips to dealers and dyno to figure all this out is hard but it is paying off. I won't stop until it's within 1% of all the great sled's dyno'd.

Summary: this has only rev'd 8200 RPM tops ever and the digital wrench history backs this up. I clutched and geared it to 8100 RPM as it fell hard after this.All my field testing proved what I was doing was correct to dyno sheets.

All dyno runs are done in three's and consistant with every sled done at DTR to keep it the same results.

First:engine temp was around 75f and rev'd around 7000RPm to get pipe heat to 900f

second:engine temp was around 120f now and get pipe to 1000f

third:engine temp was over 135f+ and pipe a good 1050f+

put on something new and repeat............

This sled makes HP to 8100 RPM and then falls hard. The other good axys dyno'd make power to 8300 RPM+.

We changed ECU's with a great dyno'd axys and still the same(thanks Heath

The problem was the bsfa's were to rich(mid 0.65's) from 7200 RPM up. The cfm's were down a little. Afr was ok. We needed to get the bsfa's down and the cfm's(scfm) up.

This sled made around the same HP and torque right up to 7500-7600 RPM as great sled's dyno'd then started falling after this. This is why I'm mentioning the bsfa's and scfm's. This seemed to be hurting this sled up top. From 7600 to 8400 RPM. There are ways to get this down and up.

After tons of dyno runs,we suspected the pipe, pipe sealing and muffler(back pressure). We put another pipe on that fit better and snug around the y-pipe and tried it.This run showed promise as the bsfa's came down(mid 0.55's) and the scfm's came up 7.The stock pipe was not putting heat in the pipe and the is why the bsfa's were in the mid 0.65's and scfm's were down. When in this state the sled would only make power to 8100 RPM and that's it.The bsfa's and scfm's were hurting this sled up top. By changing to a better pipe the bsfa's and scfm's were a lot better just because of this. Putting the pipe on brought the RPM up 150, which now made better HP and torque.Were suspected the pipe and muffler on this one and probably more out there like this particular one.

With the stock pipe on, the pipe would only get to 1050f on third dyno run. By this time the engine temp was to high.Most great HP axys sleds were getting good pipe temp at first and second dyno runs.This is were engine temp was from 90f to 120f and the pipe would reach 1050f. By the third run the engine temp was up 135f +. These were all done the same on all axys sled's so it was consistent and accurate findings.The stock pipe I had on there wouldn't get the pipe heat the great HP axys sled's did. Like I said, it toke the third dyno pull to make good pipe heat and by this time the engine temp was to high and hurt the numbers.

By putting on another pipe that fit better it made better HP/torque, brought the bsfa's down to mid 0.55's and the scfm's up 7. This also was now getting pipe heat to 1050f on the second dyno run now and the engine temp was from 110-130f which is better to have a cold engine and hot pipe. By the way,on DTR dyno the 1050f pipe temp is were these sled's are making great power but also to have a colder engine( around 110-130f).

I'm blaming the pipe,muffler/can TPS,CVT system and Polaris's poor fuel mapping from factory. To back up my findings the pipe was just proven above. The TPS are used in everything Polaris makes from quads to sxs,to sled's for years. The TPS needs to be around 0.705 volts at base, 0.913 at idle,and 4.240-4.330 at WOT. As for the poor Polaris fuel mapping. Changing the fuel and some timing ALONE gets 4-5 HP more and 2lbs of torque. I blame the warranty department for this way to safe fuel mapping. There is a lot left on the table for fuel/timing.

This is were I can see guys getting low RPM/fade in the field,all this combined. The CVT system,ECU fuel mapping,bad pipe/fitting pipe,TPS out of parameters,valves, etc.....etc......

Pulling raw fuel through the pipe makes no HP and would drop PM down in the feild, add a TPS that's richening the fuel and the bad fuel mapping,bad clutching,and this is were you'll see an RPM drop/fade I think. Sometimes the sled is pulling and putting some heat in the pipe, sometimes there's no heat in the pipe to make HP and this drops RPM everytime.

I'm including some pictures and stuff of the findings.

I hope this helps answer some questions as I have more.

Last edited: