You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Black Scorpion Project

- Thread starter axxasult

- Start date

axxasult

Active Member

http://www.upnorthtechnologies.com/order.htmlWhat's the part # of that bracket ?

Sent from Galaxy S7 using Tapatalk

axxasult

Active Member

Little more detail. people keep asking

Install Good scratchers without removing wheels for normal scratchers and those dont work with clearance issues.

Dont even start about cable scratchers. Those are junk and don't last. Wish i had a pic of my friends cables before he threw them out. They stoped touching the ground after a while and caused overheating.

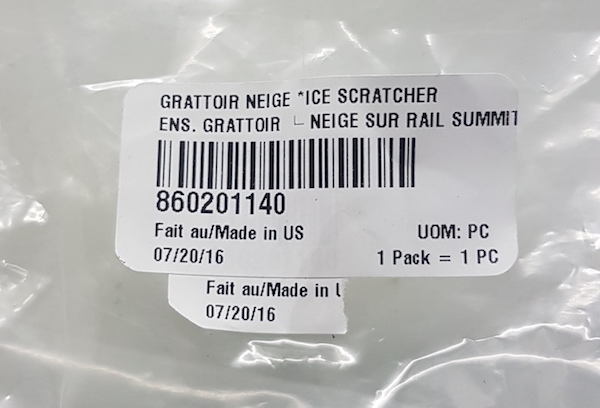

Doo Summit scratcher kit, Extra Stainless hardware. some washers and extra nuts and locknuts

Install Good scratchers without removing wheels for normal scratchers and those dont work with clearance issues.

Dont even start about cable scratchers. Those are junk and don't last. Wish i had a pic of my friends cables before he threw them out. They stoped touching the ground after a while and caused overheating.

Doo Summit scratcher kit, Extra Stainless hardware. some washers and extra nuts and locknuts

Last edited:

axxasult

Active Member

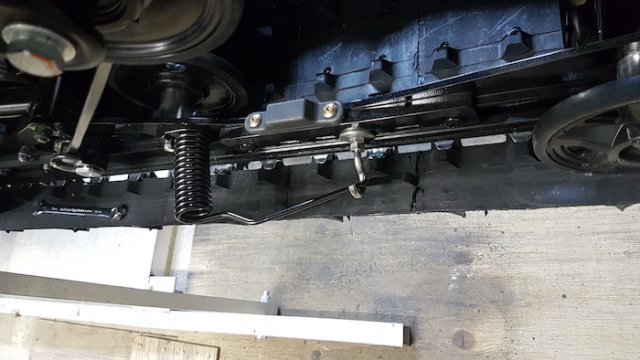

Remove rear middle wheel bolt. Use 3.25" bolts install the right bracket for the side your working on. I never took a pic without the sctracher on. On the bracket theres 2 holes. use the forward one for the wheel bolt.

With bracket bolted on drill the rear hole in bracket.

then u can install the scratcher. Use a washer on the new wheel bolt to hold the scratcher on. you can see on the pic

axxasult

Active Member

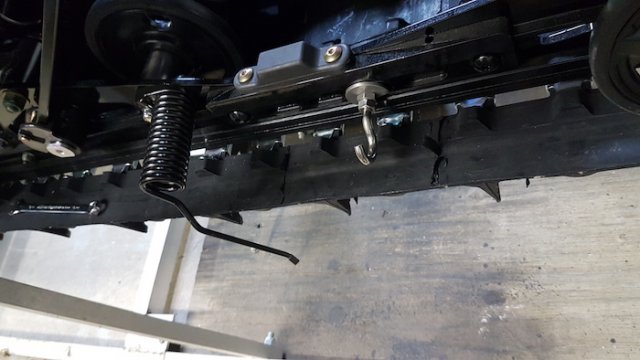

The hook is important. Cut just under half of the eye out. no less

drill the hole for eye hook in this distance..

The length of it sticking out is important.

Has to be out far enough so If you bottom out the top wheel comes down and the gap you cut out of hook allows the wheel the extra 1/2" of space. The wheel can go into the hook if u know what i mean.

you need a straight edge on top wheel and that will show you where the wheel will come down exactly. Adjust your hook as necessary.

Use 2 nuts if u can. will help support the hook sticking out. The washer i cut some off so it clears the sliders.

drill the hole for eye hook in this distance..

The length of it sticking out is important.

Has to be out far enough so If you bottom out the top wheel comes down and the gap you cut out of hook allows the wheel the extra 1/2" of space. The wheel can go into the hook if u know what i mean.

you need a straight edge on top wheel and that will show you where the wheel will come down exactly. Adjust your hook as necessary.

Use 2 nuts if u can. will help support the hook sticking out. The washer i cut some off so it clears the sliders.

axxasult

Active Member

after you get the hook stud adjusted where you wanted it. On backside allow for washer and locknut. Mark and cut off excess stud

Just double check the hook doesnt touch the track after

Just double check the hook doesnt touch the track after

axxasult

Active Member

I checked my handguards with my tall windshield today. They will work. They just touch if your turn steering full lock which you would rarely do anyways. Sweet. 90% of the time with mid windshield. If its going to be cold then 4min swap large windshield on.

Heres pics with the large dash bag on. Left the bag of when had large windshield on last time for testing.

Heres pics with the large dash bag on. Left the bag of when had large windshield on last time for testing.

JohnnyBravo

Active Member

Thanks for sharing your posts. However, my primary on both my '16 and new '17 definitely don't have that much play depicted in that video. By adding that shim kit would require machining of the spider for the shim kit to work properly as the weights will not move freely without machining. And that's just for one side. I've had this kit for a while now and noticed the same issue on both clutches. Maybe my clutches need to have a few '000+ miles to show the wear for these to work?? Not sure.

I suppose each primary clutch is different with their respective tolerances. If it were me, I'd have my spider machined on both sides of the cam weight where a stainless shim can be added on each side to help minimize wear.

I suppose each primary clutch is different with their respective tolerances. If it were me, I'd have my spider machined on both sides of the cam weight where a stainless shim can be added on each side to help minimize wear.